- This topic is empty.

-

AuthorPosts

-

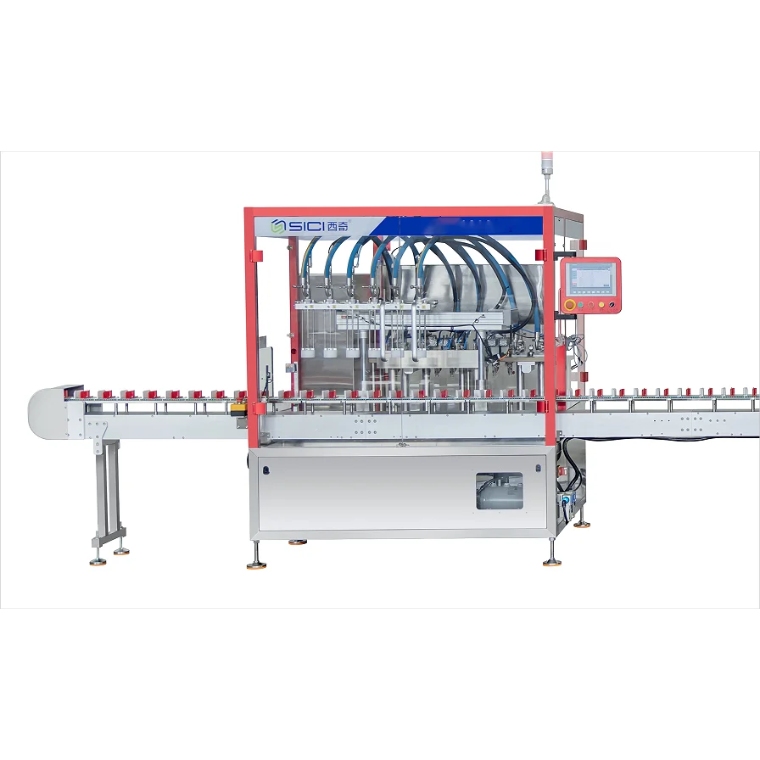

In the competitive landscape of manufacturing, optimizing production processes is crucial for maintaining efficiency, reducing costs, and ensuring product quality. Among the various technological advancements that have revolutionized production lines, SICIAUTO universal line filling equipment stands out as a game-changer, particularly for industries dealing with lotions, creams, and liquid products.

Universal Solution for Lotions, Creams & Liquid Products

Enhancing Versatility and Flexibility

Universal line filling equipment is designed to cater to a wide range of product consistencies, from thin liquids to thick creams and lotions. This versatility is a significant advantage, as it eliminates the need for specialized filling machines for each product type. Manufacturers can seamlessly switch between different product lines without extensive retooling or adjustments, thereby maximizing machine utilization and minimizing downtime.

The equipment typically features adjustable nozzles and filling speeds, enabling precise control over the filling process regardless of product viscosity. This adaptability ensures consistent fill levels and reduces waste, enhancing overall production efficiency.

Streamlining Production Workflows

One of the most compelling benefits of universal line filling equipment is its ability to streamline production workflows. By automating the filling process, it reduces manual handling and the associated risks of contamination and human error. Automated systems can also be integrated with other production equipment, such as capping machines and labeling systems, creating a seamless production line.

This integration not only speeds up production but also ensures a higher degree of coordination between different stages, reducing bottlenecks and enhancing overall throughput. Manufacturers can achieve shorter lead times and faster product launches, giving them a competitive edge in the market.

Cost Efficiency and Scalability

Investing in universal line filling equipment can lead to significant cost savings in the long run. By minimizing the need for multiple specialized machines, companies can reduce capital expenditure and maintenance costs. Moreover, the equipment's ability to handle a variety of products means that manufacturers can diversify their offerings without incurring additional equipment costs.

Scalability is another key advantage. As production demands grow, universal line filling equipment can be easily upgraded or expanded to accommodate increased capacity. This flexibility allows manufacturers to scale their operations smoothly, ensuring that they can meet market demands without compromising on quality or efficiency.

Ensuring Product Quality and Consistency

In the cosmetics and personal care industry, product quality and consistency are paramount. Universal line filling equipment plays a crucial role in maintaining these standards. The precision and control offered by automated filling systems ensure that each product is filled to the exact specified volume, minimizing overfill and underfill issues.

Furthermore, automated systems can be equipped with sensors and monitoring devices that continuously track filling parameters, such as temperature and pressure, ensuring optimal filling conditions throughout the process. This level of control helps maintain product integrity, preventing degradation or contamination that can compromise quality.

Enhancing Safety and Compliance

In addition to quality and efficiency, safety and compliance are critical considerations in manufacturing. Universal line filling equipment often incorporates safety features, such as emergency stop buttons and protective guards, to minimize the risk of operator injury. Automated systems also reduce the need for manual handling, further lowering the risk of workplace accidents.

Compliance with industry standards and regulations is another area where universal line filling equipment excels. Automated filling processes can be designed to meet specific hygiene and cleanliness requirements, ensuring that products are produced in a controlled and validated environment. This level of compliance can help manufacturers avoid costly recalls and maintain a positive reputation in the marketplace.

Universal line filling equipment offers a comprehensive solution for manufacturers dealing with lotions, creams, and liquid products. Its versatility, efficiency, cost-effectiveness, and commitment to quality and safety make it an invaluable asset in optimizing production processes. By investing in this advanced technology, manufacturers can streamline their workflows, enhance productivity, and maintain a competitive edge in today's fast-paced market.

In conclusion, universal line filling equipment represents a significant advancement in manufacturing technology, providing a one-stop solution for diverse product lines. Its ability to adapt to various product consistencies, streamline production workflows, ensure cost efficiency and scalability, maintain product quality and consistency, and enhance safety and compliance makes it a must-have for any manufacturer seeking to optimize their production processes.

http://www.siciauto.com

Wuxi Sici Auto Co.,Ltd -

AuthorPosts