- This topic is empty.

-

AuthorPosts

-

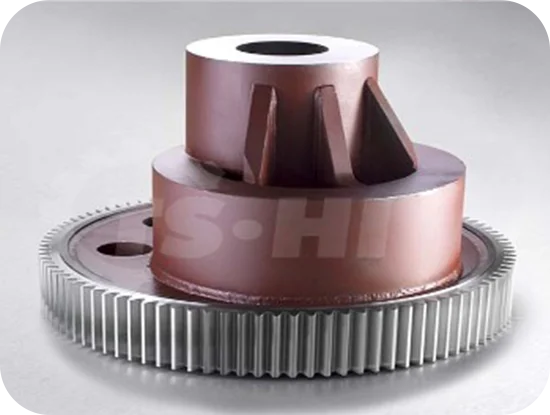

The mining industry relies heavily on robust machinery and equipment to extract valuable resources from beneath the Earth's surface. Among the most crucial components that ensure the smooth functioning of mining machinery are gears. Specifically, mining internal ring gears play an essential role in providing mechanical efficiency and operational reliability in various mining applications. These gears are critical for maintaining the operation of essential machinery, such as crushers, mills, and excavation systems, contributing significantly to the overall performance and productivity of mining operations. This article Tianshan delves into the role and applications of mining internal ring gears, offering an in-depth look at how they contribute to the success of mining operations worldwide.

The Role of Mining Internal Ring Gears in Mining Machinery

Mining internal ring gears perform several critical functions in mining machinery. Their primary role is to transmit rotational power, facilitating the operation of various mechanical components. These gears are designed to handle large amounts of torque while maintaining precision in motion transfer.

Power Transmission

The core purpose of mining internal ring gears is to transmit rotational force from one component to another. In many mining machines, internal ring gears are part of a planetary gear system, which involves sun gears, planet gears, and ring gears. The internal ring gear works with the planet gears to reduce or increase the speed of rotation, all while distributing the load efficiently. This design ensures smooth power transmission, reducing wear and tear on other components. The ability of the internal ring gear to provide precise movement allows mining machinery to operate with minimal interruption, maximizing production.

Torque Management

Mining equipment is subjected to heavy loads during operation, and internal ring gears help manage the torque that is generated by these forces. By distributing the torque evenly, these gears prevent overloading of specific components, helping to protect the machinery from potential damage. The ability of mining internal ring gears to handle extreme torque is vital for the efficient operation of mining machinery, especially in high-intensity applications like crushing or grinding. High torque can cause equipment failure or reduced lifespan, so the use of robust internal ring gears ensures that this stress is properly absorbed.

Operational Efficiency

Mining internal ring gears play a crucial role in improving the overall efficiency of mining operations. The accurate transmission of power allows for precise movement of machinery, leading to reduced operational costs and better resource management. This, in turn, enhances the productivity of mining operations, ensuring that resources are extracted effectively and quickly. The smooth operation of equipment equipped with high-quality internal ring gears contributes to the efficiency of mining operations, reducing downtime and allowing for a more continuous workflow.

Load Distribution and Longevity

One of the key advantages of mining internal ring gears is their ability to distribute heavy loads evenly across the gear system. This function significantly reduces the risk of localized wear and damage, which is especially important in mining environments where the equipment is exposed to constant stress and high operational loads. Mining internal ring gears, especially in planetary gear systems, helps minimize the wear and tear on other components, extending the lifespan of mining machinery and reducing maintenance costs.

Applications of Mining Internal Ring Gears in Mining

Mining internal ring gears are used in a wide range of mining equipment, ensuring that these machines perform reliably and efficiently under demanding conditions. The applications of these gears are vast and include the following:

Crushers and Mills

Crushers and mills are integral to the mining industry, as they break down raw materials into smaller, more manageable sizes. Internal ring gears are often found in these machines, where they help in transmitting the power needed to drive the crushing or grinding mechanism. By ensuring consistent torque transmission, these mining internal ring gears help maintain the efficiency of crushing and milling processes, which are essential for processing mined materials. In crushers, the precise control of speed and torque is critical to avoiding material damage and ensuring a consistent output size. The durability of internal ring gears in these machines is crucial to sustaining high levels of operational performance.

Excavation and Haulage Equipment

Excavators, haul trucks, and other heavy-duty machines used for excavation and transport in mining rely heavily on planetary gear systems that incorporate mining internal ring gears. These gears are used to manage the immense torque generated during operation, ensuring that the equipment can move heavy loads effectively across rough terrain. The durability and strength of internal ring gears are essential in these applications, as they ensure smooth operation and minimize the risk of failure during mining operations. Additionally, internal ring gears help in controlling the speed of movement, making it easier for operators to control the excavation and hauling equipment under challenging conditions.

Drilling Equipment

Drilling machines used in the mining industry, including rotary drills and tunnel boring machines, also employ internal ring gears. These gears help transfer rotational motion to the drill head, facilitating efficient drilling operations. By providing accurate torque control, mining internal ring gears helps optimize drilling speed and reduce wear on the drilling equipment, ensuring a longer operational lifespan. Drilling in mining operations requires high precision, as it determines the success of subsequent material extraction. The role of internal ring gears in these machines is essential to achieving consistent performance in a wide range of geological conditions.

Conveyors

Mining conveyors, which are essential for transporting materials across mining sites, use mining internal ring gears to ensure the efficient movement of materials. These gears work in conjunction with other mechanical components to provide reliable power transmission, ensuring that the conveyor systems operate smoothly and efficiently, even in high-load conditions. The operation of conveyors in mining requires continuous, reliable performance, as they transport mined material from one point to another. Internal ring gears ensure that conveyors run smoothly, minimizing the chances of operational stoppages and material handling issues.

Loaders and Shovels

Mining loaders and shovels are heavy-duty machines designed for digging and moving large amounts of earth. The large, robust gears in these machines must handle extreme forces, especially when lifting large volumes of material. Mining internal ring gears, incorporated into their planetary gear systems, helps ensure that the machinery operates smoothly under such heavy loads, providing the required torque for lifting, loading, and transporting materials efficiently.

Mining internal ring gears are essential components in the efficient operation of mining machinery. Their role in power transmission, torque management, and operational efficiency cannot be overstated. Whether in crushers, mills, excavators, haul trucks, or drilling equipment, these gears help ensure that mining operations can carry out their tasks reliably, even under the most challenging conditions. As the demand for mined materials continues to rise, the importance of high-quality mining internal ring gears will only increase. Manufacturers of these gears must continue to focus on the development of durable, efficient, and cost-effective solutions to meet the ever-growing needs of the mining industry. With the right materials, design, and manufacturing processes, mining internal ring gears will remain at the heart of mining machinery, powering the success of global mining operations.

https://www.tianshangear.com/Metallurgical-Building-Materials-and-Mining-Gear.html

http://www.tianshangear.com

Changzhou Tianshan Heavy Industry Machinery Co., Ltd. -

AuthorPosts