- This topic is empty.

-

AuthorPosts

-

The automobile industry has seen significant advancements in technology, particularly in the realm of vehicle control and safety. One of the most critical components that determine a car's handling and stability is the steering gear. High precision automobile steering gears ensure optimal driver control, responsiveness, and vehicle safety. In this blog post, Longruifa will share the manufacturing process of high precision automobile steering gear for sale, detailing each stage from material selection to quality assurance.

Step 1: High Precision Automobile Steering Gear Material Selection

The first step in manufacturing a high precision steering gear is the selection of high-quality materials. The main components, including the rack, pinion, and housing, require materials with high strength, wear resistance, and durability. Typically, manufacturers use alloy steel, carbon steel, and aluminum alloys for their excellent mechanical properties.

– Rack and pinion: Made from high-strength alloy steel to withstand repeated stress and motion.

– Housing: Often aluminum or cast iron to reduce weight while maintaining durability.

– Bearings and bushings: Use of high-quality polymers and metal alloys to minimize friction and wear.

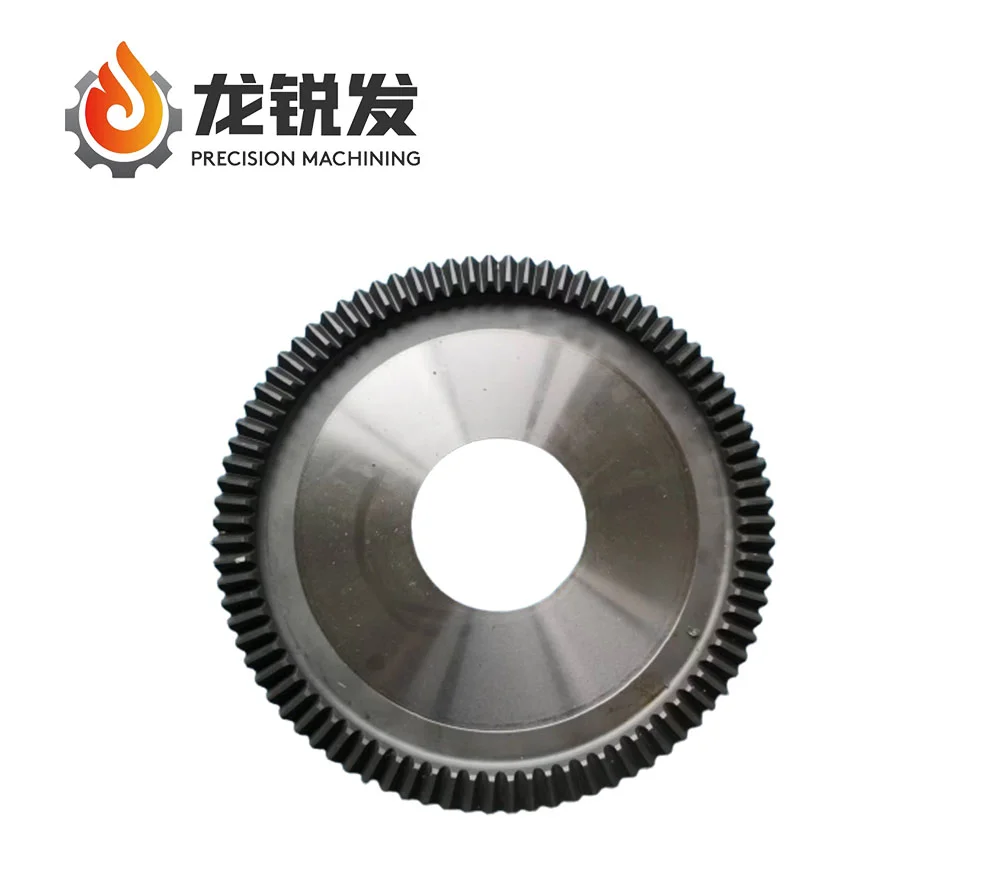

Step 2: High Precision Automobile Steering Gear Precision Machining

Once the materials are selected, the components undergo precision machining to achieve exact specifications and tolerances. This step ensures smooth operation and minimal backlash in the steering system.

CNC Machining

Computer Numerical Control (CNC) machining is extensively used in manufacturing steering gears. The rack and pinion are machined using CNC lathes and milling machines to ensure precise teeth alignment and spacing.

Gear Cutting and Grinding

– Hobbing: A specialized process where gear teeth are cut into the rack and pinion using a hobbing machine.

– Grinding: High-precision grinding machines refine the gear surfaces to achieve tight tolerances and smooth operation.

– Hardening: Heat treatment techniques such as carburizing or induction hardening improve the gear' s wear resistance and longevity.

Step 3: High Precision Automobile Steering Gear Surface Treatment and Coating

To enhance durability and corrosion resistance, the components undergo surface treatments such as:

– Electroplating: A thin layer of zinc or chrome provides protection against rust and environmental damage.

– Anodizing: Used mainly for aluminum components to increase surface hardness and resistance to oxidation.

– Phosphate Coating: Provides a base layer for lubrication and corrosion resistance.

Step 4: High Precision Automobile Steering Gear Assembly Process

After machining and surface treatment, the steering gear components are assembled with high precision and automation to ensure perfect alignment and functionality.

Key Assembly Steps:

1. Press-fitting of bearings and bushings: Ensures smooth movement of rotating parts.

2. Gear meshing adjustment: Ensuring the pinion meshes correctly with the rack to provide responsive steering.

3. Sealing and lubrication: Applying high-quality grease and installing seals to prevent dirt and moisture from affecting the system.

4. Torque testing: Ensuring that the steering gear rotates within the desired force limits for optimal performance.

Step 5: High Precision Automobile Steering Gear Quality Control and Testing

Before steering gears are shipped to automobile manufacturers, they undergo rigorous quality control and testing to ensure compliance with safety and performance standards.

Testing Methods:

– Dimensional Inspection: Using coordinate measuring machines (CMM) to check for precise dimensions.

– Load Testing: Simulating real-world driving conditions to test the gear' s durability and load-bearing capacity.

– Noise and Vibration Testing: Ensuring smooth and quiet operation.

– Environmental Testing: Exposure to extreme temperatures, humidity, and corrosion tests to verify longevity.

Step 6: High Precision Automobile Steering Gear Final Packaging and Distribution

Once the steering gear passes all quality tests, it is carefully packaged to prevent damage during transportation. It is then distributed to automobile manufacturers or spare parts suppliers worldwide.

Conclusion

The manufacturing process of high precision automobile steering gear is a meticulous procedure that requires advanced technology, high-quality materials, and stringent quality control measures. From material selection and machining to assembly and testing, each step plays a vital role in ensuring superior performance, safety, and longevity of the steering system. As the automotive industry evolves, innovations such as electric power steering (EPS) and adaptive steering continue to push the boundaries of precision engineering, making driving safer and more efficient.

http://www.lrfgears.com

Longruifa -

AuthorPosts