- This topic is empty.

-

AuthorPosts

-

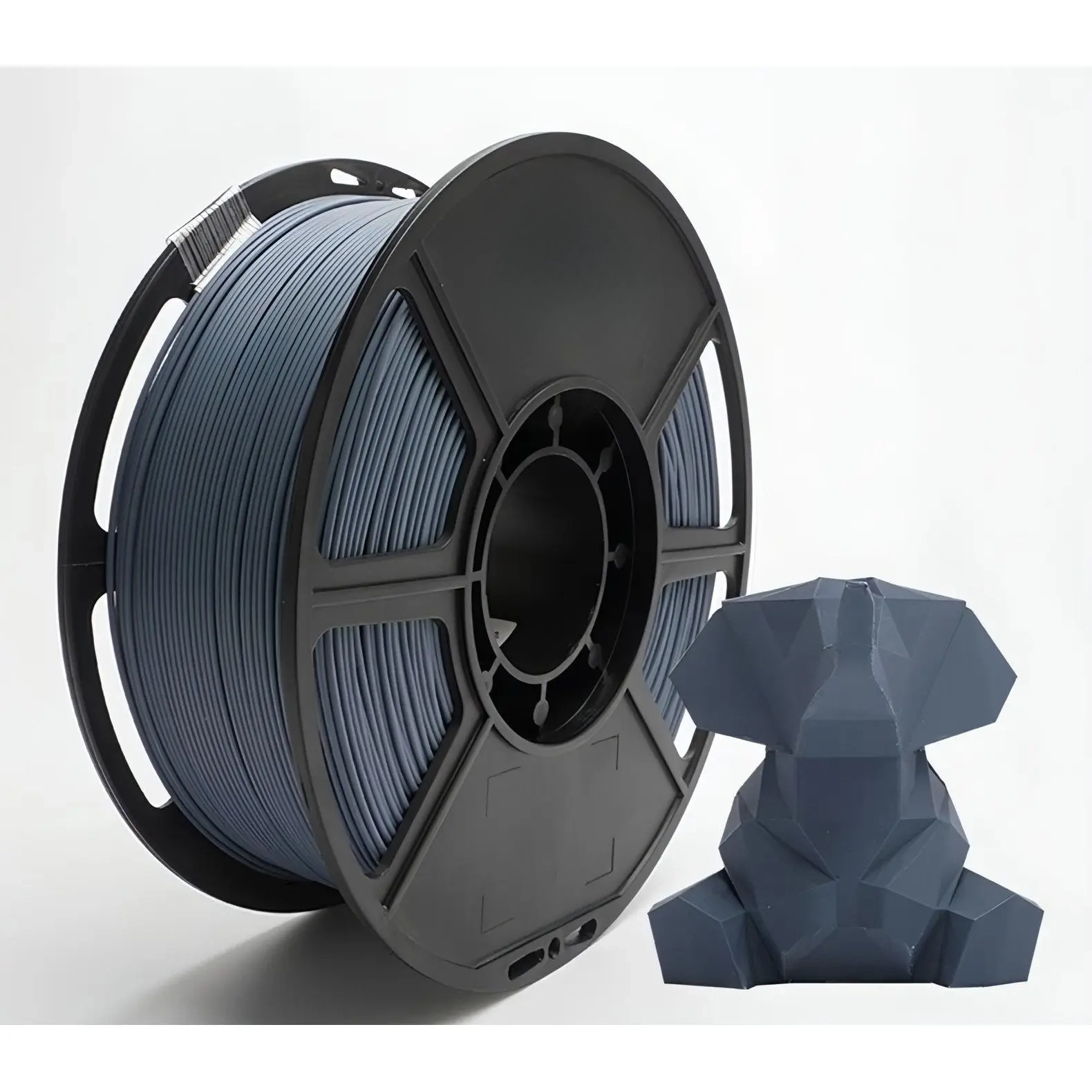

In the fast-growing industrial 3D printing market, material quality directly impacts product reliability, print speed, and overall performance. Ubest, a leading manufacturer of advanced polyester materials, has developed the UBM-2 Matte PLA Resin, which provides high toughness, uniform line alignment, and superior matte finish. Designed specifically for high-speed extrusion, UBM-2 ensures professional-grade quality and consistency for industrial 3D printing applications. By understanding the advantages of matte PLA resin, manufacturers can optimize production efficiency, reduce post-processing, and deliver high-quality products consistently.

High Toughness: Ensuring Durability in Industrial Prints

One of the primary benefits of UBM-2 Matte PLA Resin is its high toughness, which provides resilience during both extrusion and post-processing.

-

Impact Resistance: Tough resin prevents cracking during high-speed printing or complex geometries.

-

Dimensional Stability: Maintains shape under thermal stress, reducing warping and print failure.

-

Layer Adhesion: Strong interlayer bonding ensures structural integrity even for tall or intricate designs.

High toughness is particularly important for industrial parts exposed to mechanical stress or repetitive handling, such as prototypes, jigs, or functional components.

Uniform Line Alignment: Precision and Consistency

Another standout feature of UBM-2 matte PLA resin is its 100% uniform line alignment, ensuring precision and repeatability in every print:

-

Accurate Extrusion: Consistent line flow reduces stringing, blobbing, and surface irregularities.

-

Smooth Matte Finish: Even material deposition results in aesthetically appealing, professional-quality matte surfaces.

-

High-Speed Printing: Supports extrusion speeds of 30–500 mm/s without compromising print quality.

Uniform line alignment is crucial for industrial applications where tolerance, surface smoothness, and detail accuracy directly impact downstream assembly or functionality.

High Matte Finish: Professional Aesthetic and Functional Benefits

Matte PLA resins provide a soft, low-gloss finish that enhances both visual and functional aspects of industrial 3D prints:

-

Reduced Reflection: Matte surfaces minimize glare, useful for optical components or display prototypes.

-

Post-Processing Friendly: Easier to paint, coat, or bond with other materials.

-

Premium Look: Industrial-grade parts appear high-quality without additional finishing.

This high matte quality reduces the need for sanding or polishing, saving production time and labor costs.

Minimal Die Flash: Cleaner Output and Efficiency

UBM-2 is engineered for minimal die flash, reducing material wastage and print imperfections. Benefits include:

-

Less manual cleanup after printing.

-

Reduced rework, saving time and cost.

-

Cleaner and more consistent extrusion, which improves printer longevity by avoiding nozzle clogging.

Comparative Advantages Table

Feature Standard PLA Resin Matte PLA Resin (UBM-2) Toughness Medium High Line Alignment Uniformity Moderate 100% Uniform Matte Finish Low High Print Speed Capability 50–200 mm/s 30–500 mm/s Post-Processing Requirement High Low Die Flash Moderate Minimal This table highlights the industrial advantages of matte PLA resin, especially for high-speed and precision-dependent 3D printing applications.

Applications of Matte PLA Resin in Industrial 3D Printing

UBM-2 Matte PLA resin is widely used in sectors where toughness, precision, and finish quality matter:

-

Industrial Prototyping: Durable, accurate, and visually professional prototypes.

-

Functional Components: Jigs, fixtures, and end-use parts with high mechanical requirements.

-

Consumer Products: Matte finish enhances aesthetics for display items or customized industrial parts.

-

High-Speed Production: Supports rapid printing without compromising quality, reducing time-to-market.

FAQ: Matte PLA Resin for Industrial 3D Printing

Q1: Can matte PLA resin be used on all FDM printers?

Yes, UBM-2 is compatible with most professional FDM 3D printers designed for PLA extrusion.Q2: What printing speeds are optimal for UBM-2?

It supports high-speed printing between 30–500 mm/s depending on printer configuration.Q3: Is the resin environmentally friendly?

Yes, matte PLA resin is green, safe, and biodegradable under industrial composting conditions.Q4: Does it require post-processing for a smooth finish?

Minimal post-processing is needed due to the high matte finish and uniform line alignment.Q5: How does toughness affect industrial part performance?

High toughness improves layer adhesion and impact resistance, ensuring functional reliability under mechanical stress.

Conclusion

For industrial 3D printing, matte PLA resin offers unparalleled advantages in toughness, uniform line alignment, high-speed extrusion, and a premium matte finish. Ubest's UBM-2 Matte PLA Resin combines these features with eco-friendly materials and stable processing, enabling manufacturers to achieve better consistency, reduced post-processing, and enhanced durability in their 3D printed parts. By choosing Ubest, companies can rely on a trusted global supplier that provides high-quality materials and innovative solutions for modern industrial applications.

http://www.wxubest.com

Wuxi Ubest New Material Technology Co., Ltd. -

-

AuthorPosts