- This topic is empty.

-

AuthorPosts

-

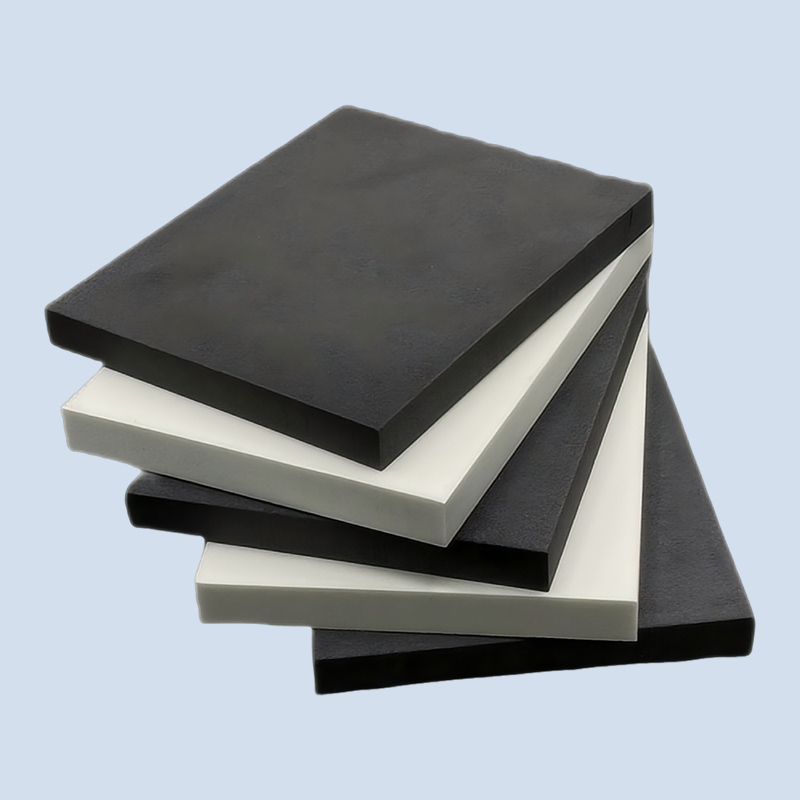

CR foam pads, made from chloroprene rubber, are versatile materials widely used in industries ranging from electronics and automotive to packaging and medical devices. Known for their durability, flexibility, and excellent thermal and mechanical properties, CR foam pads provide cushioning, insulation, and vibration absorption.

Understanding CR Foam Pads

Chloroprene rubber (CR) foam is a synthetic material with a closed-cell or open-cell structure, offering unique advantages such as:

Thermal Resistance: CR foam maintains performance under high and low temperatures.

Chemical Stability: Resistant to oils, solvents, and weathering.

Mechanical Cushioning: Excellent shock absorption and compression recovery.

Electrical Insulation: Suitable for electronic applications requiring non-conductive materials.

High-quality CR foam pads from Dubang Materials are engineered to meet rigorous industrial standards, providing reliable performance across various environments.

Types of CR Foam Pads

CR foam pads come in different forms, each tailored to specific industrial needs:

1. Closed-Cell CR Foam Pads

Closed-cell CR foam pads feature airtight cells that prevent the passage of liquids and gases. Key characteristics include:

High compressive strength and excellent rebound.

Water and moisture resistance, making them ideal for sealing applications.

Superior vibration damping and impact resistance.

Applications: Automotive gaskets, electronic device cushioning, protective packaging, and sealing solutions where water or moisture exposure is a concern.

2. Open-Cell CR Foam Pads

Open-cell CR foam pads have interconnected cells, which allow air and fluids to pass through. Their properties include:

Softer, more flexible feel compared to closed-cell foam.

Enhanced breathability and cushioning for sensitive surfaces.

Good sound absorption due to the porous structure.

Applications: Acoustic insulation, ergonomic cushioning, mattress padding, and packaging for delicate instruments.

3. Adhesive-Backed CR Foam Pads

Some CR foam pads come with adhesive backing for easy installation. Advantages include:

Quick and secure attachment to surfaces without additional bonding agents.

Consistent positioning and reduced assembly time.

Available in both open-cell and closed-cell forms.

Applications: Electronic component mounting, protective pads for machinery, and DIY projects requiring reliable adhesion.

4. High-Density CR Foam Pads

High-density CR foam pads are engineered for applications that demand extra load-bearing capacity. Features include:

Excellent compression resistance for heavy equipment.

Improved vibration and shock damping under repeated stress.

Long-lasting performance even under continuous load.

Applications: Industrial machinery vibration isolation, automotive engine mounts, and structural padding in heavy-duty environments.

5. Low-Density CR Foam Pads

Low-density CR foam pads are softer and more lightweight, offering:

Gentle cushioning for delicate or sensitive items.

Easy compressibility and conformability to irregular surfaces.

Lightweight solutions suitable for portable applications.

Applications: Packaging for fragile electronics, protective padding for medical devices, and cushioning in consumer products.

Applications Across Industries

CR foam pads are highly versatile and used in various sectors:

Electronics: Protecting circuit boards and components from vibration and thermal stress.

Automotive: Reducing noise, vibration, and harshness (NVH) in vehicles.

Packaging: Cushioning fragile goods during shipping.

Medical Devices: Providing soft, durable padding for patient care and equipment.

Construction: Sealing gaps, insulating surfaces, and preventing drafts or moisture penetration.

The specific type of CR foam pad chosen depends on the intended application, environmental exposure, and mechanical requirements.

Advantages of Using CR Foam Pads

CR foam pads offer multiple benefits that make them essential in industrial design and manufacturing:

Durability: Long lifespan even under extreme environmental conditions.

Flexibility: Conforms to irregular shapes and surfaces for consistent protection.

Vibration Damping: Reduces noise and protects sensitive components.

Thermal and Chemical Resistance: Maintains integrity in demanding applications.

Easy Installation: Options with adhesive backing simplify assembly and reduce labor costs.

These advantages make CR foam pads a preferred choice across multiple industries where reliability and performance are critical.

Selecting the Right CR Foam Pad

To select the appropriate CR foam pad, consider the following factors:

Application Environment: Will it be exposed to moisture, heat, or chemicals?

Mechanical Requirements: Determine load, compression, and vibration damping needs.

Material Type: Choose between open-cell, closed-cell, high-density, or low-density variants.

Installation Method: Consider adhesive-backed options for ease of assembly.

Dimensional Requirements: Ensure the pad size and thickness meet design specifications.

Consulting with suppliers like Dubang Materials ensures that the selected CR foam pad meets performance standards and project requirements.

Conclusion

CR foam pads are essential materials for cushioning, insulation, vibration damping, and protective applications across diverse industries. By understanding the different types—closed-cell, open-cell, adhesive-backed, high-density, and low-density—engineers and designers can select the right pad to meet mechanical, thermal, and environmental demands. High-quality CR foam pads from Dubang Materials offer reliability, durability, and performance, ensuring optimal results for industrial and commercial applications.

-

AuthorPosts