- This topic is empty.

-

AuthorPosts

-

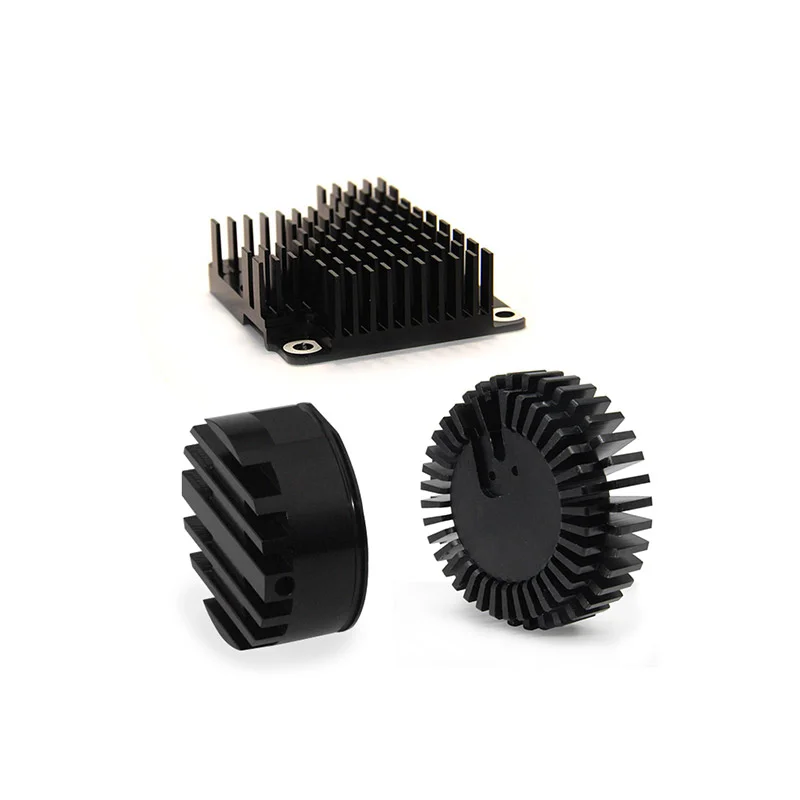

In the era of high-performance electronics and rapid technological advancements, effective thermal management is more critical than ever. Aluminum heatsink service offers tailored solutions to meet specific cooling requirements, ensuring devices operate at optimal temperatures, prolonging their lifespan, and enhancing overall efficiency. In this blog post, Vibo, a high precision custom machining service exporter, will share the importance of custom aluminum heatsink service, including manufacturing process.

Importance of Custom Aluminum Heatsink Service

Electronics generate heat during operation, and if not managed properly, excessive heat can lead to performance degradation, component damage, or complete system failure. While standard heatsinks are readily available, they often fail to meet the unique needs of specialized applications. A custom aluminum heatsink service ensures that the thermal management solution is specifically designed for the device’s heat dissipation requirements, installation constraints, and performance expectations.

Aluminum is the preferred material for many heatsinks due to its high thermal conductivity, lightweight nature, and cost-effectiveness. When combined with custom engineering, aluminum heatsinks can deliver precise thermal performance tailored to the customer’s operational environment.

Design Flexibility and Engineering Expertise

Custom aluminum heatsink services provide unparalleled design flexibility. Clients can specify exact dimensions, fin configurations, surface finishes, and mounting options to ensure seamless integration into their systems. The design process typically involves:

-

Thermal Analysis – Using advanced simulation software, engineers predict heat flow and optimize fin geometry for maximum cooling efficiency.

-

Mechanical Design – Ensuring the heatsink fits perfectly within the device’s space constraints while maintaining structural strength.

-

Material Optimization – Selecting the right aluminum alloy to balance thermal performance, weight, and durability.

-

Surface Treatments – Applying anodizing, powder coating, or other finishes to improve corrosion resistance and aesthetic appeal.

Manufacturing Process of Custom Aluminum Heatsinks

A professional custom aluminum heatsink service uses advanced manufacturing techniques to ensure precision and quality. Common processes include:

1. Extrusion

Extrusion involves forcing heated aluminum through a die to create the desired profile. This method is ideal for producing heatsinks with consistent cross-sections and is cost-effective for medium-to-high volume production.

2. CNC Machining

For complex geometries or tight tolerances, CNC machining is the preferred method. It allows for precise shaping, drilling, and milling of heatsink components, ensuring an exact fit for specialized applications.

3. Die Casting

Die casting is used when intricate shapes or integrated mounting structures are required. It offers high repeatability and allows for the creation of complex designs in a single manufacturing step.

4. Bonded Fin Assembly

Bonded fin heatsinks combine high thermal performance with lightweight construction. Fins are mechanically bonded to the base, allowing for higher fin density and increased surface area.

5. Skiving

Skiving creates thin, high-density fins directly from a single block of aluminum, maximizing surface area without additional assembly steps.

Key Advantages of Choosing a Custom Aluminum Heatsink Service

Opting for a custom solution provides significant benefits compared to off-the-shelf products:

-

Optimized Thermal Performance – Tailored designs ensure maximum heat dissipation efficiency for specific operating conditions.

-

Perfect Fit – Dimensions and mounting configurations are matched to the device, reducing installation complexity.

-

Material Efficiency – Engineers can select aluminum alloys with the right balance of conductivity, strength, and weight.

-

Enhanced Durability – Surface treatments improve resistance to environmental factors such as moisture, chemicals, and oxidation.

-

Brand Integration – Custom finishes and shapes can align with a company’s branding or product aesthetics.

Applications Across Industries

Custom aluminum heatsink services cater to a wide range of industries, each with distinct cooling needs:

-

Electronics and Telecommunications

-

Cooling for processors, power amplifiers, and communication modules.

-

Thermal management for 5G base stations and network infrastructure.

-

Automotive

-

Electric vehicle power electronics, LED lighting systems, and battery management systems.

-

LED Lighting

-

Efficient cooling for high-power LED fixtures to maintain brightness and extend service life.

-

Renewable Energy

-

Solar inverters and wind turbine controllers require effective thermal control in outdoor environments.

-

Industrial Machinery

-

Motor drives, welding equipment, and control systems benefit from robust custom cooling solutions.

Comparing Custom and Standard Heatsinks

While standard heatsinks offer lower upfront costs and faster availability, they often fall short in performance-critical applications. Custom aluminum heatsink services provide:

Feature Standard Heatsink Custom Aluminum Heatsink Service Thermal Efficiency General-purpose Optimized for specific heat loads Design Fit May require modifications Perfectly matched to application Production Flexibility Limited Wide range of shapes, sizes, and finishes Long-Term Performance Adequate in mild conditions High reliability in demanding environments

Quality Assurance and Testing

A reliable custom aluminum heatsink service incorporates rigorous quality control measures, including:

-

Dimensional Inspections – Ensuring precise adherence to client specifications.

-

Thermal Testing – Verifying heat dissipation performance under simulated operating conditions.

-

Material Certification – Confirming aluminum alloy properties for consistency and reliability.

-

Surface Finish Checks – Assessing coating thickness, adhesion, and corrosion resistance.

Conclusion

A custom aluminum heatsink service delivers precision-engineered thermal management solutions tailored to the unique demands of modern electronics and industrial applications. By leveraging advanced design tools, specialized manufacturing processes, and rigorous quality control, these services provide superior performance, durability, and integration capabilities. As technology continues to evolve, the role of custom aluminum heatsinks will only become more vital in ensuring the reliability and efficiency of critical systems

-

-

AuthorPosts