- This topic is empty.

-

AuthorPosts

-

https://www.goldenabrasives.com/Heated-Aluminum-oxide-abrasive-net

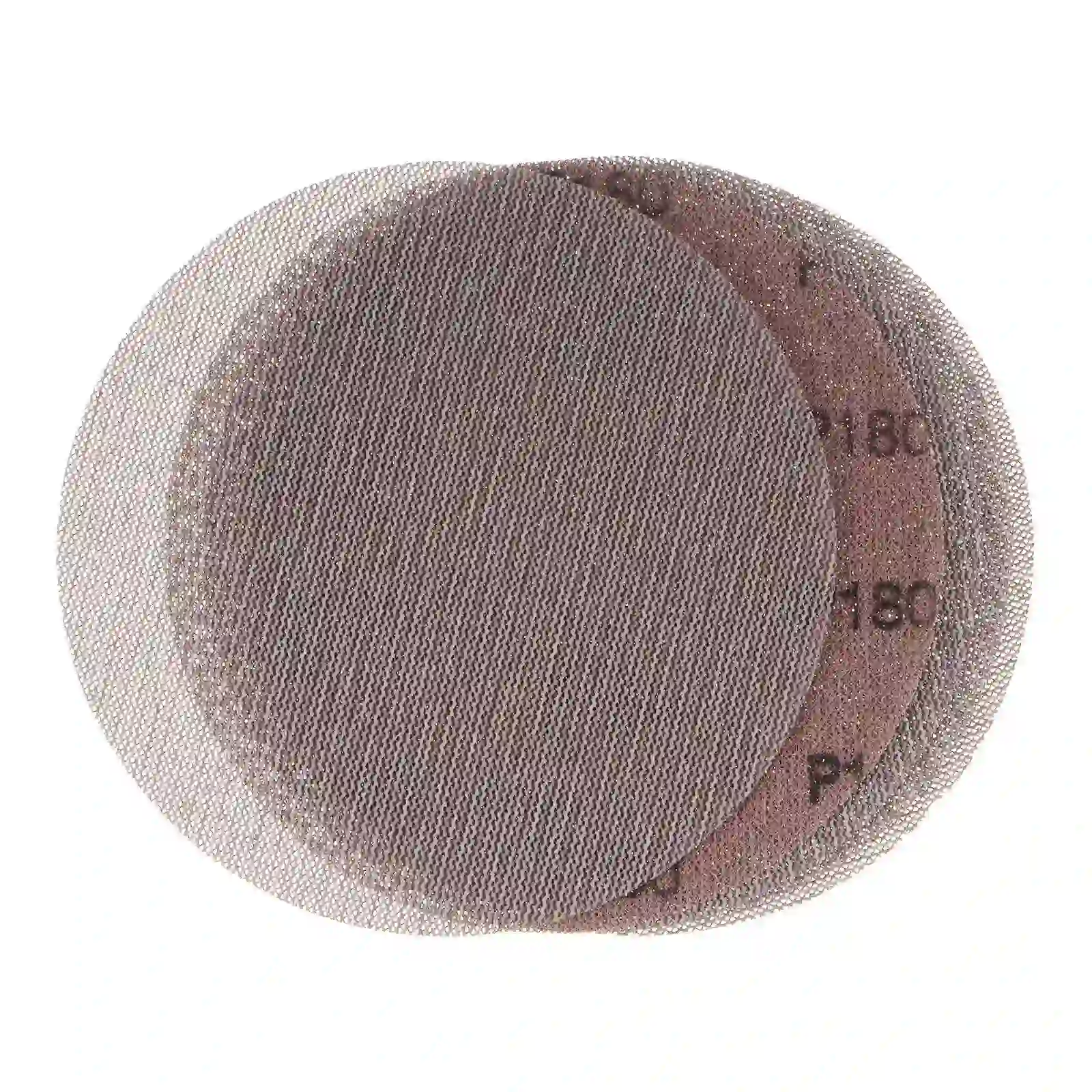

When it comes to high-performance surface conditioning, sanding, and grinding applications, selecting the right abrasive material is crucial for achieving exceptional results. One such innovative solution that stands out in industries such as automotive, metalworking, and woodworking is the heated aluminum oxide abrasive mesh. Known for its exceptional durability, adaptability, and performance, heated aluminum oxide abrasive mesh has become the go-to choice for professionals looking for a reliable abrasive that delivers consistent results across a variety of demanding environments.

Golden Abrasives has developed a specialized heated aluminum oxide abrasive mesh that meets the rigorous demands of high-intensity grinding and sanding tasks. Featuring calcined aluminum oxide particles combined with an enhanced open-weave backing, this abrasive mesh provides superior cutting performance and efficiency in multiple applications, including automotive, metal processing, and woodworking.

What is Heated Aluminum Oxide Abrasive Mesh?

Heated aluminum oxide abrasive mesh is an advanced abrasive material commonly used in industrial sanding and grinding processes. It is made from calcined aluminum oxide grains, which are fused at high temperatures to enhance their hardness and durability. These grains are then adhered to an open-weave PA net backing, which gives the material its unique flexibility and ability to conform to various shapes while still providing excellent cutting performance.

Heated aluminum oxide abrasive mesh is an advanced abrasive material commonly used in industrial sanding and grinding processes. It is made from calcined aluminum oxide grains, which are fused at high temperatures to enhance their hardness and durability. These grains are then adhered to an open-weave PA net backing, which gives the material its unique flexibility and ability to conform to various shapes while still providing excellent cutting performance.The heated aluminum oxide abrasive mesh features a closed coating that ensures the abrasive surface remains uniform and effective throughout the sanding or grinding process. The mesh backing also helps in improving airflow and reducing the likelihood of clogging, allowing for efficient material removal and longer-lasting abrasiveness.

This combination of high-quality abrasive grains and the flexible backing makes heated aluminum oxide abrasive mesh suitable for a wide range of surface preparation, conditioning, and finishing applications.

What Makes Heated Aluminum Oxide Abrasive Mesh Stand Out?

The heated aluminum oxide abrasive mesh offers a range of features that set it apart from traditional abrasive materials. From its ability to handle high-intensity applications to its versatility across various industries, this product is engineered for superior performance.

The heated aluminum oxide abrasive mesh offers a range of features that set it apart from traditional abrasive materials. From its ability to handle high-intensity applications to its versatility across various industries, this product is engineered for superior performance.1. High Durability for Heavy-Duty Applications

The heated aluminum oxide abrasive mesh is designed to withstand even the most demanding sanding and grinding applications. With its premium heated aluminum oxide grain structure, this abrasive mesh maintains a sharp cutting edge for an extended period of time, even under high pressure or aggressive usage. The combination of calcined aluminum oxide grains and the resin-over-resin bonding ensures long-lasting durability and resistance to wear, making it ideal for high-volume industrial settings.

The PA net backing provides additional strength and flexibility, enabling the abrasive to perform consistently over long periods of time without breaking down or losing its effectiveness. This makes Golden Abrasives heated aluminum oxide abrasive mesh an excellent choice for industries such as automotive, metalworking, and woodworking, where reliable performance is essential for achieving high-quality finishes.

2. Enhanced Cutting Performance

One of the standout features of heated aluminum oxide abrasive mesh is its superior cutting ability. The use of premium heated aluminum oxide grains gives the abrasive mesh a higher cutting rate compared to other abrasives, which means it can quickly and efficiently tackle tough surfaces. Whether you're sanding through tough metals, wood, or coatings, this abrasive mesh delivers fast cutting action, reducing the time required to complete tasks and enhancing productivity.

In particular, Golden Abrasives heated aluminum oxide abrasive mesh performs excellently in primer sanding applications and when working with hardwoods or solid surfaces. The fine grit range of P80-P1000 makes it versatile for both aggressive material removal and fine finishing, ensuring that the final surface meets the desired specifications.

3. Optimized Open-Weave Net Construction

The open-weave net backing is another key feature that enhances the performance of the heated aluminum oxide abrasive mesh. This construction allows for the efficient removal of debris and dust during the sanding process, which prevents clogging and ensures consistent cutting performance throughout the job. The open net design also reduces heat buildup during heavy sanding, which can cause premature wear or damage to the abrasive material.

The unique design of the net provides flexibility, allowing the abrasive mesh to conform to the surface being worked on while ensuring that the abrasive material remains firmly in place. This provides users with a reliable and efficient sanding solution that works across a variety of surface types and shapes, making it a go-to choice for intricate or detailed work.

Conclusion

Golden Abrasives heated aluminum oxide abrasive mesh provides a reliable, durable, and efficient solution for a wide variety of industrial applications. Designed for high-performance surface conditioning and sanding, this abrasive mesh delivers exceptional cutting power, flexibility, and reliability in even the most demanding environments.

Whether you're in the automotive, metalworking, or woodworking industry, heated aluminum oxide abrasive mesh from Golden Abrasives ensures optimal performance, efficiency, and quality. With its premium heated aluminum oxide grain, enhanced backing, and versatile grit options, it's the ideal choice for professionals seeking superior results in their sanding and surface preparation tasks.

http://www.goldenabrasives.com

China Golden Abrasives -

AuthorPosts